Quick Links

I'm an amateur woodworker. I'm not entirely unskilled, but I'm not a professional or even exceptional. I've never sold anything I've built. Despite that, I spent $2,200 on a SawStop table saw and got rid of an old $300 table saw. And it's worth every penny, because of its superb fence, large surface area, and ability to protect me from serious injury.

My old table saw, a portable style saw (sometimes called job site), was a gift, and it fit into my cramped two-car garage nicely. When I didn't need it, it folded up and away, and when I was ready to use it, a quick press on a pedal unfolded it. But for my most recent projects, that table saw just didn't cut it.

Ok, it cut things, but not straight. The fence system was pretty terrible and often went out of alignment. I might have thought I had a straight cut, but I often found out later everything I did was crooked.

Due to its portable nature, it had a small surface area, which made handling even a half sheet of plywood nearly impossible without help. That made large projects difficult at best. No, I needed something with a much better fence, more surface area for material, and safety mechanisms to prevent me from permanently injuring my hand. Because I almost did that once.

A Superior Fence That Glides and Stays Straight

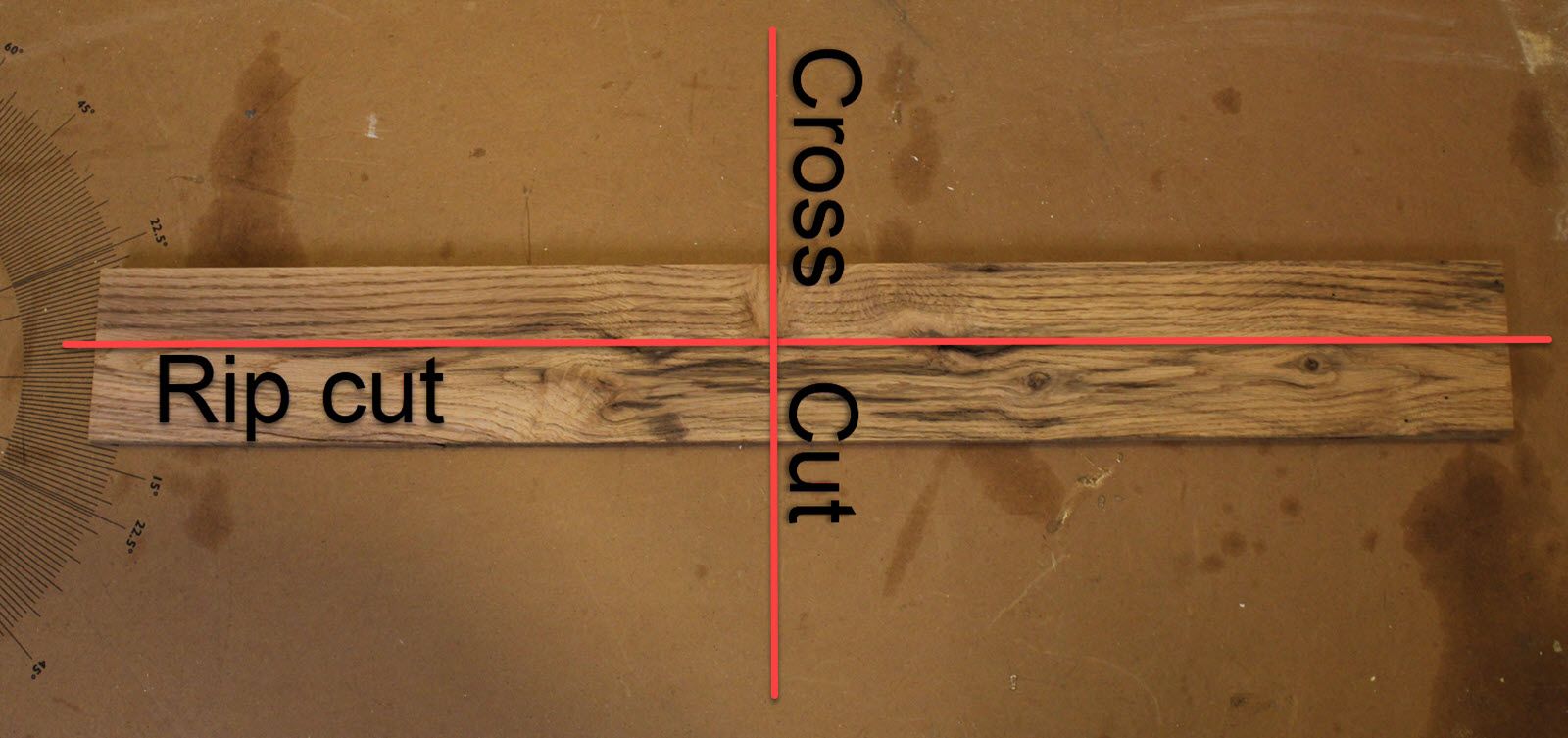

Table saws primarily make two kinds of cuts: crosscut and rip cut. When you buy a piece of wood, typically, it's longer than it is wide. A crosscut shortens the board, while a rip cut narrows the board.

Every table saw comes with a fence to make rip cuts happen. It runs parallel to the blade (and miter slots), and you can slide it left and right to determine how narrow you want to cut. But if your fence is out of alignment and pointed at a diagonal compared to the blade, you won't get a straight cut.

On my old table saw, the fence had two locking mechanisms, one at the front and one at the back. You pulled up on each to unlock the fence, then pushed left and right. The fence itself was very narrow and didn't slide across the table smoothly. That lead to issues where the back of the fence was slightly askew compared to the front. And thus, you got crooked cuts.

For nearly that reason alone, I chose to skip SawStop's jobsite saw, despite a considerable difference in price. I stepped up to a contractor saw, which let me upgrade to a T-Glide fence. As the name implies, the fence resembles a T, with the crossbar running across the front side of the table saw.

That cross bar helps lock the fence in place and allows it to glide smoothly from one side of the surface to the other. When you have it in position, you lower a handle, and it locks. Because of that single mechanism, the fence locks straight, giving you a straight cut.

With my old table saw, I often found myself adjusting and readjusting to get a straight fence, only to find I still ended up with crooked cuts. With my SawStop, I slide, lock, and get a straight cut every time. That saves me time and money by avoiding wasted materials.

A Bigger Surface for Bigger Projects

I am still an amateur at woodworking, but my skills are progressing. With that comes larger projects and materials. Recently I've been creating benches, desks, and floating shelves. That can mean working with sheets of plywood or live edge slabs that I need to cut down.

For some things, a circular saw is still the better option, but with a large enough surface area to work with, a table saw can help. My old portable saw could handle at most a 1/4th sheet of plywood. I need more.

The fence I wanted requires at minimum a contractor saw, the portable jobsite version doesn't offer it. So, I solved two birds with one stone, I stepped up to the larger contractor saw, which got me the fence I wanted and more surface area.

Whereas my old saw's top is 47 inches, 20 inches of that is unsupported airgap. The fence slides out with two bars to create more space. My new saw's top is 68 inches and wholly supported. Now, I can cut large pieces, and thanks to the extra support, I can do so more safely. But that isn't all that makes this table saw safer. It can prevent an accident that might otherwise cut my fingers off---something I nearly did once.

I (Probably) Won't Cut My Fingers Off

Warning: The following section discusses potential injuries and details that may make some readers squeamish or uneasy.

Table saws are dangerous. Anyone who tells you differently is either lying or doesn't properly respect their tools. It's easy to see why they're dangerous: this is a tool that cuts through wood and metal. You are not harder than wood or metal, so anything that can cut through wood can cut through you.

Because of the nature of a table saw's spinning blade, it can cut through you and drag you in it, making a bad injury worse. According to the U.S. Consumer Product Safety Commission, there were 33,400 table saw emergency department-treated injuries in 2015 alone.

In 2018 just before I started writing for How-To Geek, I was one of them. While trying to complete a project in a hurry, I made a cut using poor technique. The table saw grabbed the wood piece and threw it at me. That missed, but I flinched and brushed my finger across the spinning blade. I got incredibly lucky; I permanently lost the middle-portion of my fingernail. But I kept my finger. It could have much worse; I easily could have mangled my entire hand. I nearly ended my writing career before it started.

I learned a lot of lessons that day, and I'm more vigilant about safety protocols now. But here's the thing: I knew better. I knew better than to work in a hurry and use such poor technique---and I did it anyway. I grew complacent with my tool and safety, and I made a stupid human mistake. Mistakes happen, sometimes through conscious choice or slips, and I don't want to run that risk again. And that's where SawStop comes in---it has superpowers.

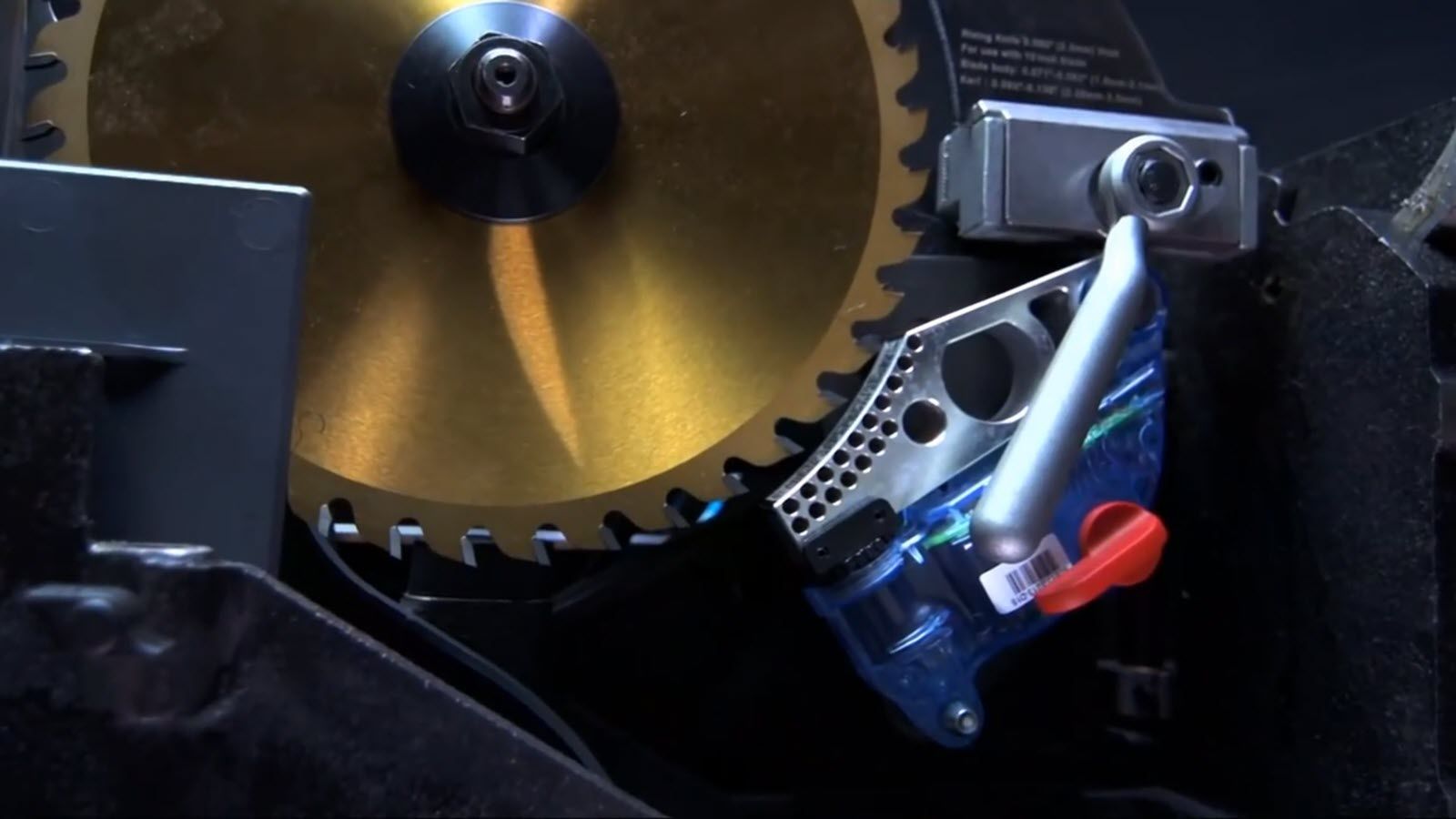

A SawStop table saw comes with an extra component, a flesh-detecting sensor. It runs a current of electricity through the blade and monitors the signal. If you touch the blade, that changes the signal and sets off the safety system. Within milliseconds brake slams into the blade, which stops the spin and pulls it down below the table surface. After that happens, you can replace the brake and blade, and get back to work.

Check out this slow-motion demonstration on a hot dog:

Even when jammed through at unreasonable speeds, the SawStop system reacted and dropped the blade. After injuring myself and realizing how it could have been a life-changing event, I evaluated my situation and made several decisions and promises.

- If completing a project today means working in a hurry, I'll wait until tomorrow

- I will always use proper technique, including the use of push sticks and push blocks.

- I'll use every bit of safety equipment available. The cost of an expensive saw is undoubtedly less than the price of an ER visit and a missing appendage.

That final decision informed my choice to buy a SawStop table saw. I saved up and purchased it as soon as possible.

Making it Mobile

If you look at the SawStop website, you'll see that the option I chose is just under $2,000. But I said I spent $2,200. The price of this build fluctuates, but that's not the whole story. I needed maneuverability. My workshop is a 2-car garage, and when winter comes I shut the workshop down. We park our cars in the garage through the winter, and it's a tight fit. To that end, I needed a way to move the 258-pound SawStop easily and store it away.

So, I sprang for the $250 mobile cart. That not only gives my table saw wheels, but I can tip on its side when winter comes. At that point I can store it against the wall, leaving room in the garage for both cars.

The mobile cart comes with downsides---it's not quite as stable, and some accessories aren't compatible with it. But for my scenario, it's perfect. Alas, it's no longer sold and the closest you can get is a mobile base, which still let you move around the saw stop with ease, but not tip it on its side.

I Love This Saw

So, how do I like my SawStop table saw? I love it. Soon after I started using it, I discovered additional benefits I hadn't even taken into consideration. Despite being larger and more powerful than my old portable saw, it's half as loud, and it shakes less. That latter bit is more comforting than I can describe in words.

Thanks to a more powerful motor, I have an easier time cutting hard and exotic woods. Purple Heart caused my old saw to struggle, but now I cut through it like butter. That gives me cleaner cuts, and I finish sooner.

Even the wheels I use to lift and lower the blade or change its angle are a joy to use compared to my old saw. They're larger, so I need fewer turns to make significant changes, and yet they feel smoother. It's a giant step up in quality, as it should be.

I'm still vigilant about safety, but I feel less stressed knowing I have a backup system if I make a mistake. That means I'm using my table saw for cuts that I might have avoided before---not because they can't be done safely, but because I feared my tool too much.

Dropping $2,200 on anything, let alone a table saw, isn't something I can do at the drop of a hat. It involved sacrifice and saving. But now that I have it, I know the effort and money spent is justified.